| Product price | $10.00 |

| Ship from | JRP7+PRQ, Baoan, Shenzhen, Guangdong Province, China |

| Supply ability | 200000 pieces / month |

| Avg. production time | 12 days |

| Product packaging | Paperboard boxes |

| Shipping packaging | Wooden box |

| Incoterms | EXW |

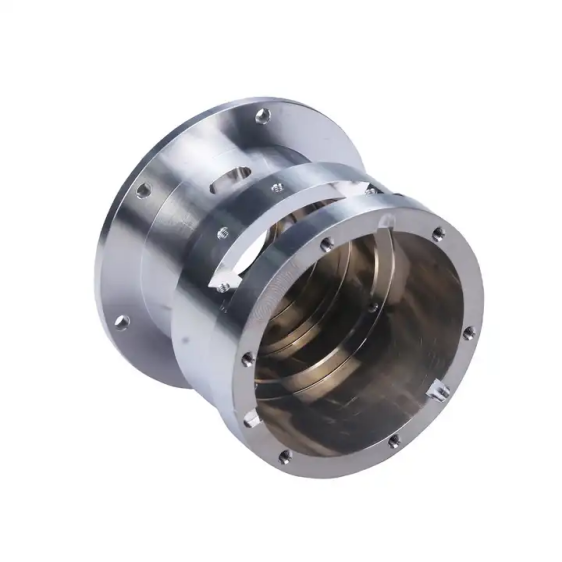

We are Ideal Group, specialized in custom machining with more than 15 years experience, with 150+ employees, experienced management personnel and a group of highly skilled workers. Our main process technology :

1, CNC machining (3/4/5 axis)

2, Vacuum Casting

3, SLA/SLS/3D PRINTING

4, Low volume production

5, Lathing/turning process

6, Sheet Metal

7, Rapid Injection Tooling

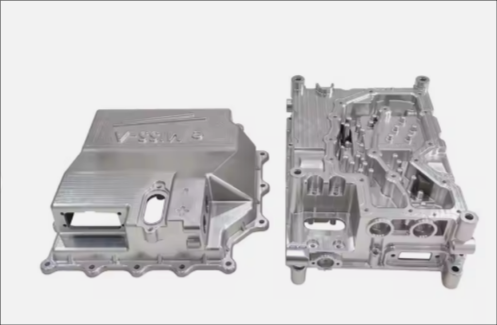

8, Die casting

9, Vacuum forming

10, injection molding

11,die-casting

We can very accurately address the specific standards and requirements of the automotive, electronics, home appliances and telecom industries. In addition, Ideal performs general plastic product analysis, product development, mold manufacturing, injection molding and other high technology services in many other fields. Ideal can provide customers with a range of products from small, high precision molds to large size molds.

The product types range from large automotive parts, home appliance plastic housings (monitor, TV, iron, vacuum cleaner, stereo, etc.), plastic cases for phones, plastic game machine housings, furniture accessories and plastic housings for a variety of consumer electronics (calculators, MP4 cases, PDA translators, GPS, printers, etc.). Ideal's plastic parts are assembled by the customer into products exported to Japan, Europe and America. A full 50% of molds are exported directly to Europe and Japan. Company Quality Policy is simple - "To ensure quality by management, to ensure progress by quality, to ensure interest by progress".