Stainless steels are a family of alloys with an iron base, available in a huge variety of grades. It is one of the most widespread alloys used in practically every industry. This material is notable for its durability and easy cleaning while being easy to CNC machine, weld, and form.

Order in Stainless Steel

| Property | Value |

|---|---|

| Service temperature | -452.2°F (-269°C) and 1900°F (1035°C) * |

| Density | 8000 kg/m³ ** |

| Stencile strength | 600 MPa |

| Elastic Modulus | 193 GPa |

| Endurance (fatigue) limit | 240 MPa |

* Depends of the grade of the alloy, ** Grade 304

Stainless steel alloy usually contains iron, chromium, manganese, silicon, carbon, and sometimes nickel and molybdenum. This material is used in almost every industry and technology (like CNC machining and milling) as it's both strong and has good corrosion resistance. However, after sustained contact with water, it can eventually corrode. Stainless steel has lots of different types (grades) that each has various properties depending on the additives they contain, though a minimum of 10.5% of chromium is a must. The main grades of stainless steel are:

Machined stainless steels have, on average, quite shiny silver surfaces, which can be treated in many ways, including powder coating, polishing, and blasting.

3D printing with stainless steel is available in several different technologies from powdered or extruded material.

316L is one of the most popular stainless steel grades used in 3D printing. This material has better mechanical properties thanks to the high temperature gradient and fast rate of solidification, though some printers are able to print with 17-4 PH as well.

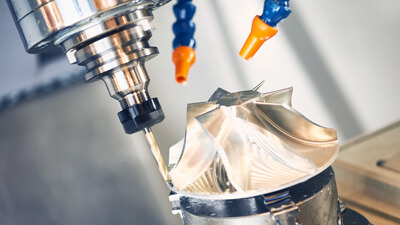

Stainless steels are easy to machine on CNC mills and lathes to good mechanical tolerances with great repeatability. Machined stainless steel parts are suitable for many applications and can be manufactured to ISO standards.

The huge advantage of machining with this material is that stainless steel exhibits so-called self-repairing, which means the surface repairs itself from scratches due to chromium content in the stainless steel.

Stainless steels for laser cutting are available in different forms such as angles, beams, tubes, and more. Laser cut steels have precise edges and small radii, they appear highly refined.

Forming or stamping of stainless steels is sometimes chosen for repetitive better production rates, especially for thick-gauge steels. For elongated, shallow or simple stainless steel shapes it is possible to perform a fluid cell forming process. Steel would go under high pressure to form it in geometry with tight tolerances. The main advantage is that several high-quality parts can be formed at one time. Additionally, the forming process causes lower surface abrasion, reducing post-processing.

All Comments (0)