MDF stands for Medium-density fiberboard - a material engineered from wood fibers bound and pressured together with resin or wax to form a panel. MDF stands out for its affordability - being formed from wood cutting byproducts, these panels and boards are quite budget friendly. Though having their downsides, MDF panels are widely used for indoor applications and construction.

Order in MDF (Medium-density fiberboard)

| Property | Value |

|---|---|

| Bending strength | >40 N/mm2 * |

| Modulus of elasticity | >3000 N/mm2 * |

| Thermal conductivity | 0.10 W/(m·K) ** |

* for 6-9 mm thick board, ** for mean density 600 kg/m3

MDF is a type of engineered wood alongside plywoods, OSB, and others. This material can be described as a middle ground between plywood and chipboard and finds its own applications thanks to fine properties combined with affordable price. Panels may vary in density, though, on average are heavier and denser than plywoods and HDF. Primary use fields of MDF are the indoor applications, otherwise, sealing of edges and surface are advised to preserve panels from damage.

Due to its nature and particle-based structure, MDF has certain downsides such as high absorption rates, which are commonly compared to that of a sponge. This adds limitations to the material used as it intakes moisture or wood stain at very high rates. Additionally, MDF warps and damages quickly once sucking in moisture.

Improved variations of MDF are available on the market with special labels standing for:

HDF stands for high-density fiberboards, which, on average, are heavier and denser than MDF. There is a slight overlap between the two at about 600-800 kg/m3, although HDF panels may be as dense as 1450 kg/m3.

Generally speaking, plywood appears a more reliable, resistant, and lightweight material. However, due to the cost difference or a need to have some flexibility to a product, MDF may be a better option for certain applications. It is worth taking into consideration the part's expected application (indoor or outdoor) as well as the properties of both materials to establish the best option for your specific needs.

OSB stands for Oriented Strand Board, manufactured from strands of lumber, which are set perpendicularly to provide strength and stability to panels. OSB is more resistant to moisture and weather than MDF as well. However, MDF exhibits more flexibility and serves as a versatile medium.

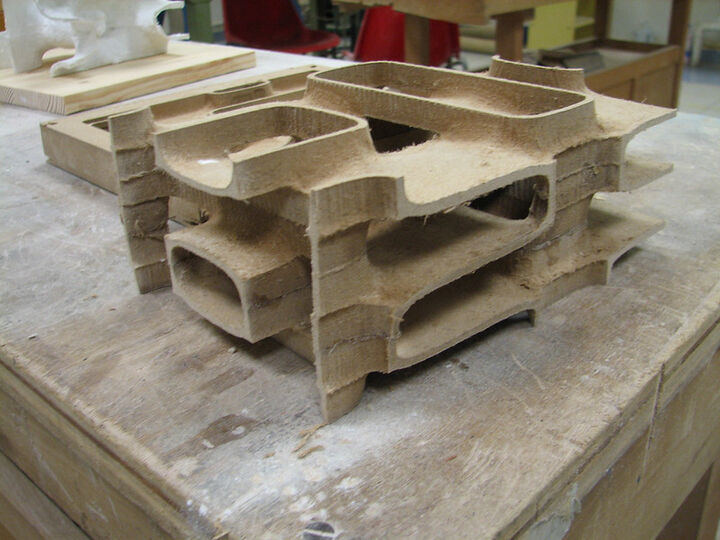

MDF is relatively easy to CNC machine, though, it is reported to cause decent tool wear and create a large volume of dust. Machined MDF panels provide good precision, and are used widely in signage, roofing, and advertisement. This material delivers a smooth surface without pores and cracks.

MDF is widely used in laser cutting for a huge range of products. The material is easy to cut and engrave, though the edges of the cuts would naturally darken. However, keep in mind that MDF may be prone to inconsistency when laser cut due to its high density.

All Comments (0)